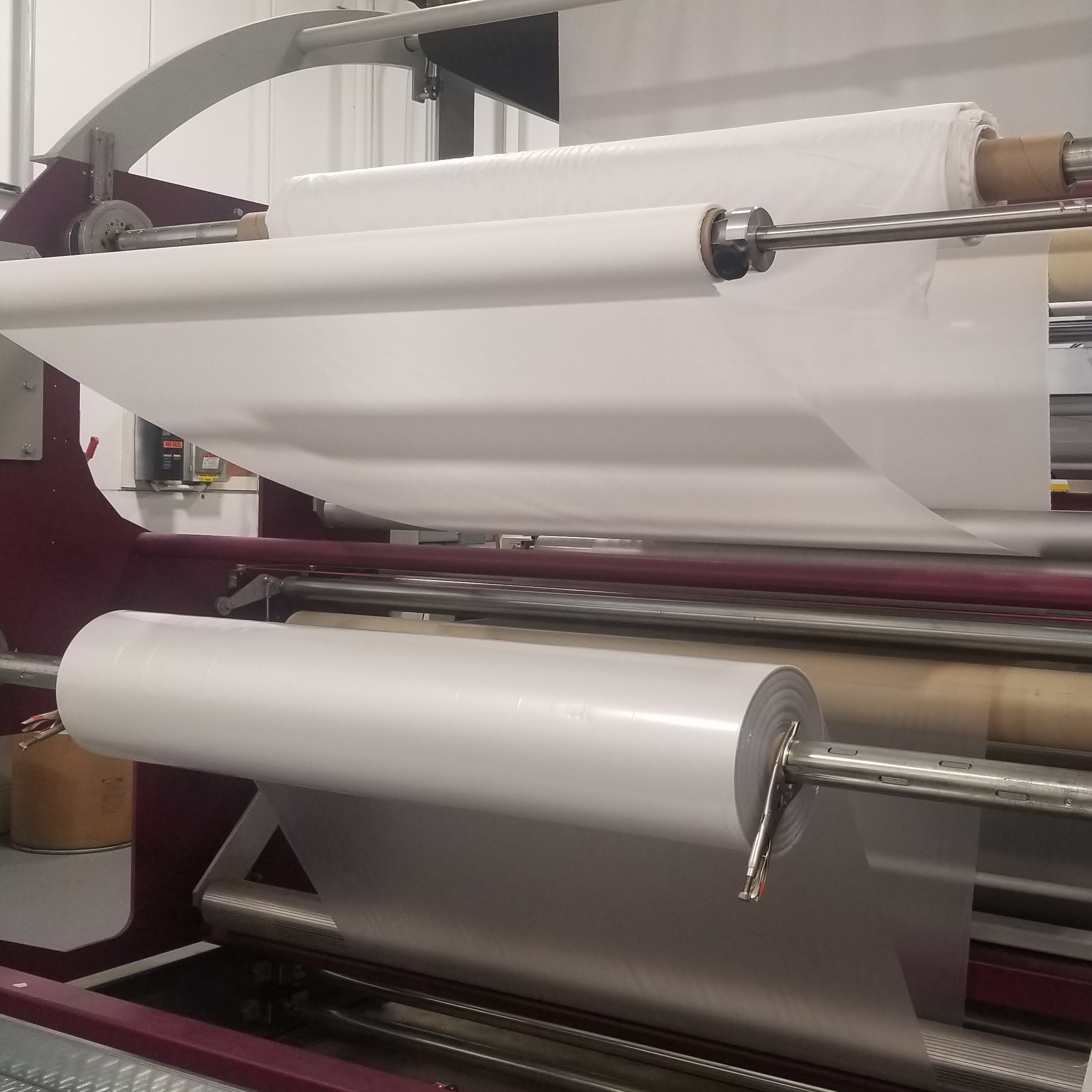

As a thermoplastic extrusion manufacturer, our extrusion lamination capabilities are somewhat apparent. However, we also offer a variety of lamination processes including coextrusion, gravure lamination, full-roll coating lamination, and belt lamination. The versatility of these lamination capabilities combined with our decades of experience processing a broad selection of substrates and materials allow Bixby to deliver innovative custom solutions to our customers in spec and on time.

PROPRIETARY, FLEXIBLE MANUFACTURING CAPABILITIES

FOR UNIQUE MONO- & MULTI-LAYER

CUSTOM PLASTIC SOLUTIONS

CAPABILITIES

- Adjustable working width up to ~90” (~228cm)

- Coating weights from 10-60 g/m2 (GSM)

- Heated anti-stick press station

- Process temperatures up to 446˚F (230˚C)

CAPABILITIES

- Adjustable working width up to ~90” (~228cm)

- Coating weights from 10-60 g/m2 (GSM)

- Heated anti-stick press station

- Process temperatures up to 446˚F (230˚C)

CAPABILITIES

- Adjustable working width up to 87” (~221cm)

- Coating weights from 10-60 g/m2 (GSM)

- Heated anti-stick press station

- Process temperatures up to 446˚F (230˚C)

CAPABILITIES

- Up to 72"(~192cm) wide film or sheet

- Gauge range: 0.003” to 0.250”

(0.0762mm to 6.35mm) - Coating gauge range: 0.001” to 0.008”

(0.0254mm to 0.2032mm) - Texturizing of materials

CAPABILITIES

- Three-layer coex laminates up to 36” wide

- Coex laminates can be extrusion laminated

onto other substrates - Gauge range: 0.001” to 0.100”

(0.0254mm to 2.54mm)

RELATED MATERIALS

Bixby has experience processing nearly every commercially available thermoplastic family. Additionally, we work with specialty, custom, and developmental polymers and formulations, hot melts, and tie layers. These can be extruded as monolayer film and sheet or combined with other substrates for the manufacture of custom laminations.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)