Throughout Bixby’s iterative development process prototypes are imagined, rapidly created, and tested against their intended performance targets. To accomplish this Bixby has established application, materials, and process testing labs for characterizing and validating the unique processes and constructions developed along the path toward your commercial launch.

LAB TESTING CAPABILITIES

APPLICATION TESTING

- QUV Accelerated Weathering –Q-Panel (UVA and UVB)

- Environmental Chamber Testing

- Freeze/Thaw

- 85˚C/85 RH

- Thermal/Humidity Cycling

- Programmable Cycles

- Vacuum/Pressure Thermal Lamination Equipment

- Compression Molding (Carver–dual and single heated platen)

- Oven Testing

- Vacuum

- Convection

MATERIALS TESTING

- Differential Scanning Calorimetry (DSC)

- MGW Lauda Polymer Sof tening Point Analyzer

- Laboratory Capillary Rheometer [Dynisco, LAB KARS (“Kayeness Advanced Rheology Software”)] for Melt Index Testing

- UV/Vis Spectrometer (Haze, YI, Light Transmittance)

- ThermoLyne Polymer Ash Testing Furnace

ANALYTICAL TESTING

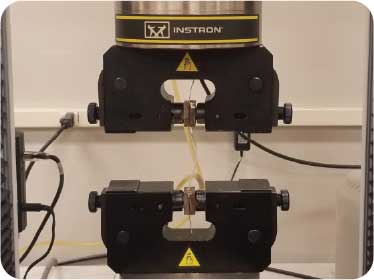

- Tensile/Compression Properties – Instron

- Flexural Properties – 3-Point Instron and Taber

- Impact Properties (Notched/Unnotched Izod & Charpy)

- Fournier Transform Infrared (FT-IR)

- Abrasion Resistance

- Coefficient of Friction

- Adhesion/Peel Strength – 90˚ and 180˚ Peels

- Burst Strength (Mullen Test)

- Satra Dome Flexural Testing

- Chemical Resistance/ESCR

- Short-Term Creep/Stress Relaxation

- Melt Index

PDF Download

Download a PDF about our Lab capabilities

Contact Us

Have a question about our processes or capabilities? Do you need a plastic solution for your next project? Are you interested in learning more about Bixby’s custom manufacturing possibilities? Contact us and we will be happy to assist!