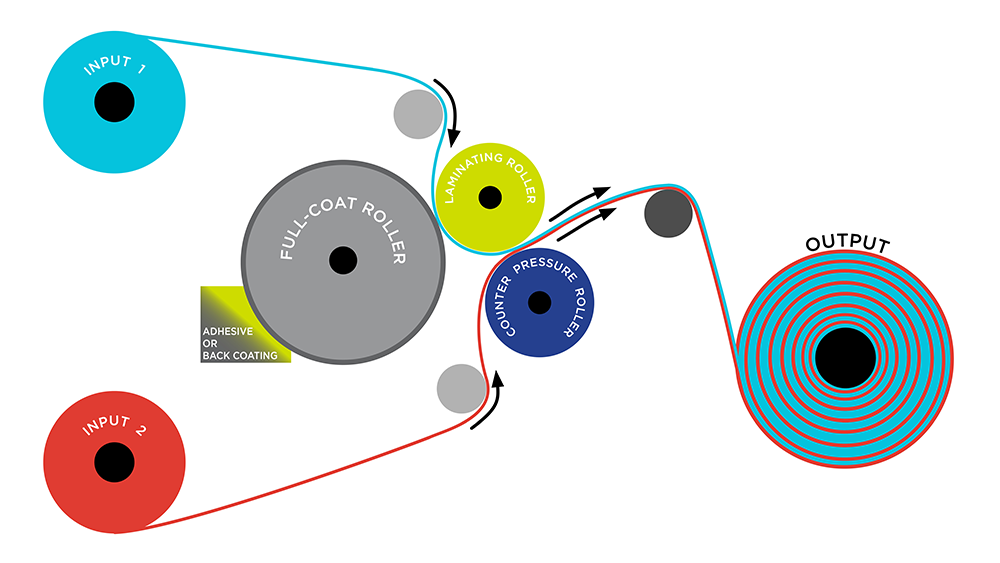

Our FULL-ROLL COAT LAMINATOR offers flexible adhesive chemistries for a variety of rolled goods. This laminating process adhesively bonds two layers of substrates with a uniform coat of adhesive.

FULL-ROLL COAT LAMINATION PROCESS

CAPABILITIES

- Specially designed equipment for lamination bonding of a broad range of substrates

- Adhesive bonding/lamination via hot-melt or reactive polymers

- Film/web thermobonding

- Plastic coatings

- Transfer/Embossing of special effects via engraved rolls (e.g. snakeskin, perforations, textures, patterns & custom specifications)

- Application of “black-out”, protective film, barrier and specialty films in unique laminates

- Driven, tension-controlled unwinding and winding of stretch or delicate input substrates and foams

- Fabric spreading technology

- Precise temperature and pressure control for cylinder and doctor blade

TECHNICAL SPECIFICATIONS

- Adjustable working width up to ~90” (~228cm)

- Coating weights from 10-60 g/m2 (GSM)

- Heated anti-stick press station

- Process temperatures up to 446˚F (230˚C)

RELATED MATERIALS

Bixby is experienced processing most every commercially available thermoplastic family. Additionally, we work with specialty, custom and developmental polymers and formulations, hot melts, and tie layers. These can be extruded as monolayer film and sheet or combined with other substrates for manufacture of custom laminations.

PDF Download

Download a PDF here

Contact Us

Have a question about our processes or capabilities? Do you need a plastic solution for your next project? Are you interested in learning more about Bixby’s custom manufacturing possibilities? Contact us and we will be happy to assist!