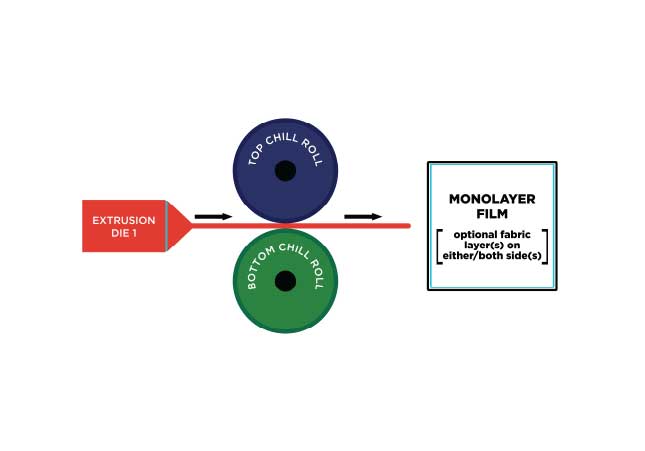

The CAST EXTRUSION process involves feeding various polymer materials and additives in the form of plastic pellets into the system. The components are then melted and homogenized in a heated extrusion barrel via a screw which mixes and pumps the molten resin through a slit die to form the extruded molten web into flat film or sheet. The material is then ‘cast’ onto or between a number of cooling rolls to be solidified and wound for use in a variety of applications. Bixby has six flat die extruders that can run individually however, when organized in tandem these make up three sophisticated cast extrusion lines in-house. Together with an experienced and dedicated manufacturing team and state-of-the-art equipment, our processes are established, controlled and monitored to quality specifications from start to finish.

CAST EXTRUSION PROCESS

CAPABILITIES

- 48” (~121cm) wide film or sheet

- 60” (~152cm) wide film or sheet

- 72” (~182cm) wide film or sheet

- Texturizing of materials to achieve preferred finish (e.g. glossy, brushed, light matte, heavy matte, prismatic or custom specifications, and embossing)

- In-house slitting available both in-line and offline

- Diverse extrusion screw and die designs allow processing of the broadest range of polymers

TECHNICAL SPECIFICATIONS

- Gauge range: 0.003” to 0.250” (0.0762mm to 6.35mm)

- Coating gauge range: 0.001” to 0.008” (0.0254mm to 0.2032mm)

RELATED MATERIALS

Bixby is experienced processing most every commercially available thermoplastic family. Additionally, we work with specialty, custom and developmental polymers and formulations, hot melts, and tie layers. These can be extruded as monolayer film and sheet or combined with other substrates for manufacture of custom laminations.

PDF Download

Download a PDF about our Cast Extrusion capabilities

Contact Us

Have a question about our processes or capabilities? Do you need a plastic solution for your next project? Are you interested in learning more about Bixby’s custom manufacturing possibilities? Contact us and we will be happy to assist!