BIXBY'S HIGH-HIDING DIFFUSERS

What is a high-hiding diffuser?

High-hiding diffusers are designed to hide LED hotpots to generate a more uniform appearance. This is often accomplished through fillers that create a more opaque diffuser to mask the view of LED hotspots, however, this can slightly limit the lighting output. Bixby’s diffuser technology does not use fillers or laminates. The high-hiding ability derives from the multi-faceted surface which masks the hotspots while allowing full light transmittance.

What diffusion angles are available?

Our standard product line angles include 80° circular, 60° circular, 20° circular, 10° circular, and an 80°x 50° elliptical output. We can also customize our diffusers to nearly any desired angle upon request thanks to our patented facet-design technology.

What sizes of LED light diffusers are available?

Depending on the customer’s unique design characteristics, Bixby’s cast extrusion lines can produce both sheet and roll goods at a range of thicknesses and widths. Thicker sheet constructions can be die-cut to accommodate custom dimensions and thinner designs can be slit internally to a specified width. Contact one of our technical experts today to learn more about which of our capabilities matches best with your design criteria.

Are you able to manufacture custom angles outside of your listed products?

Yes, Bixby’s facet design technology can be tailored directly to your needs to match almost any photometric output. This includes circular, elliptical, top-hat, and asymmetric distributions as well as custom shapes depending on the characteristics of the incoming light source.

How can I cut Bixby’s diffuser? Do I need special tools?

Depending on the diffuser material and desired thickness, cutting Bixby’s diffusers is fairly simple. Thick constructions can be die-cut and thinner constructions can be cut easily with scissors or shears.

Are Bixby diffusers waterproof?

Yes, materials such as polycarbonate, acrylic, and polyester are resistant to water.

Can Bixby LED diffuser micro facet patterns flake or delaminate over time?

No. Bixby’s light-shaping elements are incorporated directly into the bulk sheet or film material. This serves to improve durability in rigorous service environments subject to mechanical stress, UV radiation, humidity, and exposure to chemicals or cleaning products.

Are Bixby diffusers RoHS compliant?

Bixby extrudes one of the broadest portfolios of materials in the extrusion industry. We work in collaboration with our strong network of supplier relationships to implement materials that meet our customer’s needs and provide the proper certifications.

DIFFUSER SELECTION

What is the difference between Bixby’s monolayer diffusers and other diffusers?

Bixby’s diffusers aim to provide a level of customization and simplicity different than current solutions offered in the realm of LED light diffusion. Our light-bending elements are directly embossed into the sheet or film, can be extruded in a wide variety of thermoplastic materials, and can be custom tailored to fit your photometric needs.

What materials are available for optical custom development projects?

Bixby extrudes one of the broadest arrays of thermoplastic materials in the industry. Typical transparent materials such as acrylic, polycarbonate, and polyester are possible. Our network of relationships with material suppliers allows us to customize materials and additives to meet your end product requirements.

GENERAL DEFINITIONS

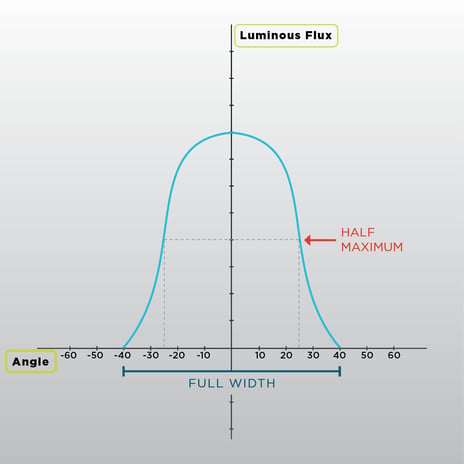

What does FWHM mean?

FWHM stands for full width at half maximum. This is a standard nomenclature to describe the angular distribution of light output. As seen in the graph below, it is important to note that a small amount of light will fall outside of the FWHM-specified angle. (Example drawing below)

What are LED hotspots?

The term LED hotspots refers to the various areas of increased light intensity within an LED light source. These are often visible as linear beams or spots within the lighting. High-hiding diffusers are designed to alleviate the visibility of these hotspots and evenly disperse the light output.

What is UGR?

The acronym UGR refers to the Unified Glare Rating. This rating measures the glare caused by a lighting system along a scale of discomfort levels caused by the artificial light output. Designers and architects use this rating score to predict and control the risk of experiencing uncomfortable glare in the designated area. UGR values can range from 40, which is an extremely high amount of glare, to 5, which is a very low glare level.

What is a light-shaping diffuser?

A light-shaping diffuser uses the micro facets embossed on the diffuser surface to manipulate the light direction and create precise angular beam control into a desired shape.

What is a monolayer embossed structure/diffuser?

A monolayer embossed diffuser incorporates an array of calculated micro-elements on the surface of a film or sheet. These elements refract incoming light to output a desired distribution of the light. This method of diffusion is often referred to as “surface diffusion”

CONTACT US

Interested in learning more about our optical capabilities and solutions? Contact us today to speak with a knowledgeable member of our team.

Specialty coated fabrics and reinforced sheet

Bixby has been supplying high-end specialty sheet products to the specialty coated fabric and reinforced sheet market for over 30 years. Our unique processing capabilities and ability to produce a diverse range of specialty plastic resins allows us to provide a diverse portfolio of products to the specialty coated fabric and reinforced sheet market.

Bixby provides both single-layer and multi-layer sheets, including sheets integrated with reinforcing scrims and woven and non-woven fabrics. Our high-end process allows us to produce sheets of the highest quality that are used to make a wide variety of coated fabrics and reinforced sheets.